Leaky Hydraulic Cylinders: 7 Common Causes and How Pros Fix Them

- PSI Hydraulics

- Jan 6

- 10 min read

A leaky hydraulic cylinder eats uptime, makes a mess, and can create safety risks if a machine won’t hold position under load. The good news: most leaks trace back to a short list of mechanical and fluid-related issues. In this guide, we’ll cover the seven most common causes of hydraulic cylinder failures, show you how to check if a hydraulic cylinder is leaking internally, and explain how professionals diagnose and repair the problem—quickly and correctly.

If you need help now, you can request cylinder repair & replacement. For a deeper look at our teardown, inspection, and testing workflow, see the repair process. Much of what you’ll see here is built on the same engineering mindset you’ll find across PSI’s shop, highlighted on our about us page.

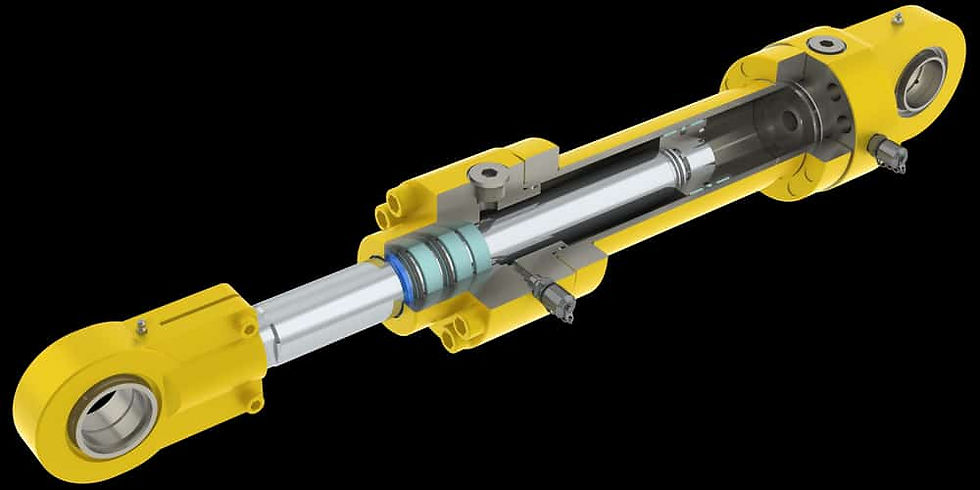

External vs. internal cylinder leaks: quick definitions

Before diving into causes, it helps to separate the two leak types:

External leak: Hydraulic oil escapes the cylinder to atmosphere. You’ll see wetness around the rod, gland, ports, or barrel seam; oil on the floor; or a wiper that’s pushing out sludge. The machine may still move normally but loses fluid and pressure cleanliness.

Internal leak (bypass): Oil crosses from the pressure side to the return side inside the cylinder—most commonly past the piston seal or through a damaged wear band or scored bore. You won’t see oil on the floor. Instead, the cylinder drifts or can’t hold load, movement feels “spongy,” or the actuator heats up abnormally during a hold.

Pros check for both, because it’s common to have light external weeping and internal bypass at the same time.

*For a broader diagnostic overview, see our related post: Cylinder Trouble? Here’s How to Spot and Stop It Early.

How to check if a hydraulic cylinder is leaking internally

Here’s a straightforward, field‑ready approach. Follow your lockout/tagout procedures and work on a clean, depressurized system. If any step is unclear or unsafe, stop and call a technician.

Drift test under load

Extend the cylinder to a marked position with a steady load applied (e.g., raised boom or clamped fixture). Neutralize the valve and watch the rod or position indicator. Uncommanded movement (downward creep or retraction) suggests internal bypass. Note the rate—fast drift points to significant seal or bore damage.

Cap‑end isolation

With the machine safely blocked, disconnect and cap one port at a time (start with the rod-end), then re‑pressurize the opposite side. If the cylinder still moves or pressure won’t hold, oil is likely crossing the piston seal or a cracked wear band is letting the piston rock.

Pressure decay / thermal check

Pressurize the cylinder to a typical working value and hold. Watch gauge decay without any commanded motion. A steady pressure drop and slight temperature rise in the return line or valve body can indicate bypass flow heating the circuit.

Listen and feel

With the valve in neutral hold, a faint hissing in the cylinder body and a warm return hose often point to internal leak‑by.

Eliminate valve leakage

To rule out a control valve issue, deadhead the cylinder with both ports capped (where safe and appropriate) or swap work lines with a known‑good function. If drift persists with ports isolated, the cylinder, not the valve, is the culprit.

This isn’t a substitute for a bench test, but it gives you a confident yes/no on internal leakage and helps decide the next step.

The 7 most common causes of hydraulic cylinder failures and leaks

1) Rod seal wear and wiper failure (external leak)

Symptoms: Oil collecting on the rod or at the gland, oily dust on the wiper, streaks down the barrel, increased contamination in the reservoir.

Why it happens: Dynamic rod seals wear over time. Abrasive particles get pulled past a tired wiper and cut the lip. Heat, pressure peaks, and side‑loading accelerate the wear. A nicked rod or poor surface finish will chew a new seal almost immediately. When inspecting rods, techs look not only at seal condition but also at the surfaces and components supporting the circuit. This includes checking nearby hydraulic lines, especially hydraulic tubing routed around mobile cylinders, since poor routing can cause abrasion and side load.

Pro fix:

Replace the rod seal set and wiper with the correct profile and material (polyurethane U‑cup or PTFE cap with elastomer energizer, depending on pressure and temperature).

Inspect the rod. If chrome is pitted or the finish is rough, polish or rechrome to a seal‑friendly surface (smooth finish in the dynamic range).

Verify rod alignment and mounting to reduce side load.

On dusty jobs, upgrade to a heavy‑duty metal‑cased wiper.

*For additional early-warning signs and inspection tips, see our related post: How to Spot Hydraulic Cylinder Failure Before It Costs You.

2) Piston seal wear or blow‑by (internal leak)

Symptoms: Cylinder won’t hold position, drifts under load, feels weak even with full pump pressure; movement may be jerky near the ends of stroke.

Why it happens: The piston’s sealing element wears, extrudes from pressure spikes, or hardens with heat/chemical attack. A cracked or worn wear band allows the piston to “tilt,” opening a path for bypass. During teardown, PSI’s team uses precision measurement tools—part of the same equipment used across our fabrication department, including engineering, fabrication tools, and custom machining stations—to confirm whether wear bands and seal grooves are still in tolerance.

Pro fix:

Bench‑test the cylinder, disassemble, and reseal with the correct piston seal profile and wear band thickness.

Carefully inspect the bore for scoring or ovality (out‑of‑round). Hone lightly if within tolerance; re‑tube if damage is deep or ovality is excessive.

Match seal material to fluid and temperature (e.g., FKM for higher heat/chemicals, HNBR for better toughness, PTFE for low friction/high pressure).

3) Bent or scored rod and poor surface finish

Symptoms: Premature rod‑seal failure after a fresh reseal, “polished” stripes on one side of the rod, seal lip fragments in the gland, wiper popping out.

Why it happens: Side load or impact bends the rod slightly. Even small TIR (runout) forces the seal to track eccentrically, cutting the lip. Surface damage—from corrosion, weld spatter, or grit—acts like sandpaper. This is one of the most common issues found in heavy industry environments like pipe mills and plate mills, where side load is high and contamination is unavoidable. These applications demand robust cylinder builds and regular inspection cycles.

Pro fix:

Measure rod straightness and runout; straighten or fabricate a new rod if out of spec.

Strip and rechrome if pits or rust are present; finish‑grind and polish to the proper smoothness for dynamic seals.

If the application inherently side‑loads, consider adding a guide or changing to a mounting style that permits misalignment (e.g., spherical bearings/clevis).

*For a deeper look at how cylinder reliability impacts demanding environments, see our related post: The Role of Cylinder Services in Heavy-Duty Industries.

4) Cylinder tube scoring, ovality, or cracked welds

Symptoms: Persistent internal bypass even after reseal; metallic sheen in oil; external seepage at a barrel weld or at the head cap; “chatter” during movement.

Why it happens: Contamination embeds in the seal and drags across the bore. Side‑load pushes the piston hard against one side, wearing the bore into an oval. Thermal cycling and stress can fatigue a weld on welded‑body cylinders. If a re-tube is required, the barrel may be replaced or fabricated using the same capabilities we use for custom projects and hydraulic power units. Having fabrication and machining in-house eliminates delays and ensures the new tube meets the exact fit, tolerance, and finish requirements.

Pro fix:

Inspect ID with light and bore gauge. Hone to restore crosshatch if damage is shallow; re‑tube if scoring is deep or ovality is measurable.

Dye‑penetrant or mag‑particle test suspect welds; reweld and pressure‑test to spec.

Replace worn wear bands to re‑establish piston guidance.

5) Contamination and fluid breakdown

Symptoms: Frequent seal failures, sticky operation, valve spools hanging up, dark or milky oil, sludge at the wiper, filters loading quickly.

Why it happens: Dirt, water, and metal fines abrade seals and corrode chrome. Wrong fluid choice or heat oxidizes oil, hardening elastomers and reducing lubricity. Contamination also often originates from hose or connection issues. PSI fabricates custom hose kits in-house using components from our trusted manufacturers: Couplamatic Systems, Fittings Unlimited Inc., Stucchi USA, and Tompkins Industries. Using quality fittings and assemblies helps prevent the debris and ingress that destroy seals prematurely.

Pro fix:

Flush the system, replace filters, and clean or replace breathers.

Verify fluid type and viscosity for the operating temperature.

Add desiccant breathers or kidney‑loop filtration on severe‑duty equipment.

During rebuild, choose seal materials compatible with your fluid and temperature envelope.

*For a broader look at how cylinder services support equipment reliability and extend service life, see our related post: What Are Cylinder Services and Why Are They Essential for Your Equipment?.

6) Overpressure and pressure spikes

Symptoms: Extruded seals, nicks on seal lips, split backup rings, fractures around the head gland, or blown tie‑rod seals.

Why it happens: Relief valves set too high, abrupt directional changes, or sudden stops can spike pressure above working limits. Some applications also see thermal expansion when a cylinder is locked in a hot environment. Some customers request system checks as part of PSI’s onsite service, especially when repeated cylinder failures hint at overpressure or unstable relief valve settings. Onsite pressure verification can quickly isolate the root cause.

Pro fix:

Check system relief settings and function; verify cushion adjustments to decelerate the rod before end of stroke.

Consider cross‑port relief or over‑center/counterbalance valves where loads overrun the pump.

In the cylinder, use proper anti‑extrusion rings and seal profiles rated for the peak conditions.

7) Mounting misalignment and side load

Symptoms: Uneven seal wear, shiny wear marks on one side of the rod, bushing/bracket wear, unusual noises at stroke limits.

Why it happens: The cylinder and the load path aren’t aligned. Misapplied fixed mounts (e.g., rigid foot mount where a pivot mount is needed) force the rod to act like a column under bending. Misalignment issues often tie back to frame geometry, mounting hardware, or incorrectly bent lines. PSI’s hydraulic tube bending service comes into play here: properly bent tubes reduce stress on the cylinder and prevent side-load-induced wear.

Pro fix:

Inspect mounts and pins. Replace worn bushings and straighten brackets.

Change mounting style if the application calls for angular movement—use clevis, trunnion, or spherical bearings to let the cylinder self‑align.

Verify parallelism of the load rails and add guides if needed.

*If you’re watching for early indicators that point to alignment problems or cylinder stress, see our related post: Top 5 Signs Your Hydraulic Cylinder Needs Repair.

What professional cylinder repair actually looks like

Anyone can swap seals. The difference between a short‑lived fix and a reliable rebuild is process. Here’s what you can expect from a professional shop:

Intake & function test – We record failure symptoms, operating pressure, environment, and fluid type. On the bench, we run a controlled extend/retract and hold‑pressure test to confirm the complaint and gather baseline data.

Safe teardown – Fixtures protect the rod and barrel. We remove the head/gland without nicking sealing surfaces, then pull the rod/piston assembly.

Inspection & measurement –

Rod OD, straightness, and chrome condition

Bore ID, straightness, and roundness

Piston and wear band fit

Gland and port threads

Seal groove dimensions and backing ring condition

Failure analysis – We look for the root cause, not just the failed part: abrasive scoring, heat hardening, chemical attack, pressure extrusion, or misalignment clues.

Precision repairs –

Re‑seal using the correct materials (polyurethane, NBR/FKM, HNBR, or PTFE/filled PTFE as needed).

Rechrome/polish or fabricate a new rod; hone or re‑tube the barrel.

Weld repair and hydraulic rod machining & remachining for heads and caps; correct tie‑rod stretch and torque sequence on tie‑rod cylinders.

Upgrades when appropriate: heavy‑duty wipers, low‑friction piston seals, better wear bands, or improved mounts.

Reassembly & torque – New seals are installed with proper lubrication and tools. Threads get the right torque specification; ports are cleaned and plugged.

Pressure & leak testing – The cylinder is cycled across the full stroke on a test stand and held at pressure to verify no external leaks and no internal bypass at temperature.

Documentation – You receive test results and recommendations to prevent a repeat failure.

For a step‑by‑step walkthrough of how we handle these tasks, visit our repair process.

Repair vs. replace: a practical decision framework

A clean, fast reseal is often the right answer. But sometimes replacement or a partial rebuild is smarter. Use the following to decide:

Cost and lead time: If a standard‑size welded cylinder is badly scored or bent, re‑tubing plus a new rod may cost more than a new unit—unless the original had special dimensions or mounting. Custom cylinders and long‑lead OEM hydraulic parts usually favor repair.

Extent of damage:

Repair: Mild scoring, seal wear, small chrome pits, or a leaky wiper.

Replace/major rebuild: Deep bore damage, significant rod bend, cracked castings, repeated failures due to undersized components.

Duty cycle and safety: Critical lifts or personnel‑safety applications justify a more conservative rebuild standard and additional testing.

Root cause: If misalignment or overpressure caused the failure, address the system issue at the same time, or the new part will fail early as well.

Not sure which way to go? A bench evaluation provides clarity and costs far less than picking the wrong path.

*For a deeper look at what a full rebuild includes—and when it delivers the best long-term value—see our related post: Cylinder Rebuilding 101: How It Works and Why It’s Worth It.

Preventing leaks after repair: a short maintenance checklist

Keep contamination out. Maintain filter change intervals, fix reservoir breathers, and inspect rod wipers. A clean system dramatically extends seal life.

Verify pressure controls. Set relief valves correctly and tune cylinder cushions to avoid hard impacts at end of stroke.

Align the load path. Check mounts and pins during scheduled preventative maintenance; replace worn bushings and correct bent brackets.

Match seals to the job. Temperature swings, chemicals, water exposure, and high pressures all influence the best seal material and profile.

Watch early indicators. A faint oil sheen at the gland, rising operating temperature during a stationary hold, or slowing cycle times are small clues worth investigating before you get a hard failure.

Quick reference: symptoms to cause (and likely fix)

Oil on rod/gland: Worn rod seal/wiper → Reseal, polish/rechrome rod, upgrade wiper.

Drifts under load without visible leakage: Piston seal bypass → Reseal; inspect wear band and bore; hone or re‑tube if needed.

New seal failed quickly: Bent or rough rod, misalignment → Straighten/replace rod; correct mounts.

Metallic sheen in oil; chatter: Bore scoring or ovality → Hone/re‑tube; new wear band.

Repeated seal extrusion: Pressure spikes → Check reliefs/cushions; adopt anti‑extrusion backup rings.

Milky or dark oil; sticky movement: Contamination or fluid breakdown → Flush; new filters; verify oil type.

Weeping at barrel seam/head: Weld fatigue or tie‑rod issues → Weld repair and pressure test; torque tie‑rods correctly.

*If misalignment or stress in adjoining piping is contributing to cylinder wear, see our related post: Pipe Bending Services: Key Techniques and Their Benefits.

Why January is the right time to act

Demand rises in spring. Taking care of leaky hydraulic cylinder issues in January means you can rebuild during planned downtime, get ahead of parts lead times, and start the busy season with reliable equipment. It also feeds your maintenance plan for the year—better filtration, correct pressure settings, and aligned mounts prevent repeat failures.

Call the Houston team that does it right the first time

If you’re dealing with a leak—or you just confirmed how to check if a hydraulic cylinder is leaking internally and want a definitive bench test—PSI Hydraulics can help. We rebuild welded and tie‑rod cylinders, rechrome and fabricate rods, hone or re‑tube barrels, and validate performance on a test stand before it leaves our shop.

Contact us today and request a quote. Let's get your equipment back to work with confidence.

.png)

Comments